Iron

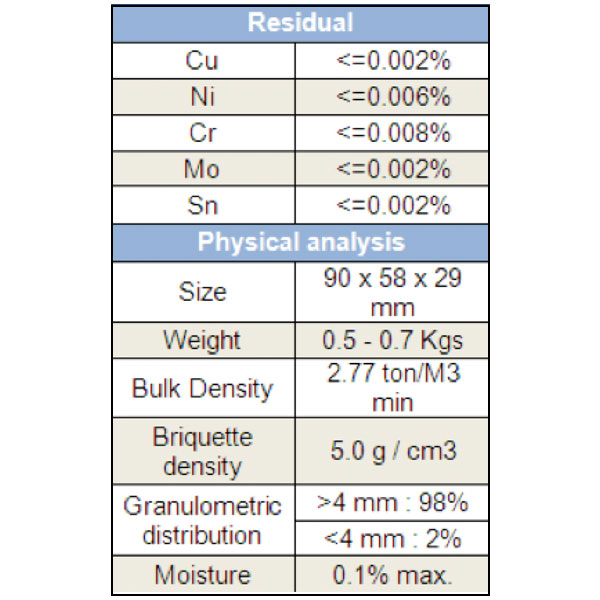

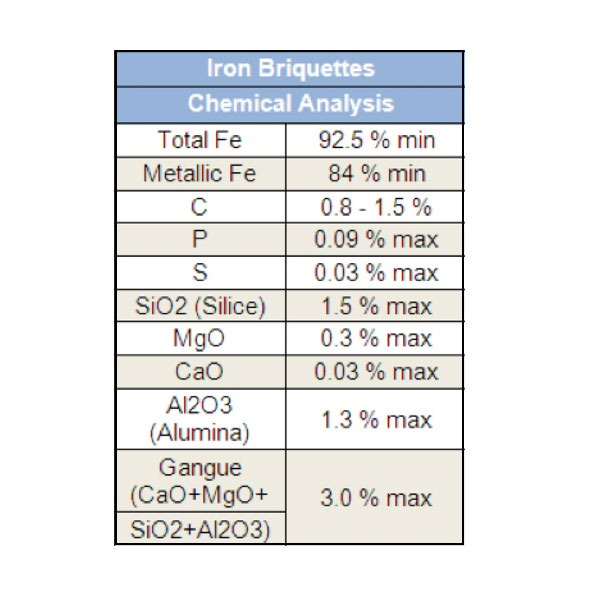

Iron briquettes are produced by reducing iron ore fines in fluid bed reactors with a counter current reducing gas (Fluidized Iron Ore Reduction). Due to their high density and metallization, low gangue and residual content, and inert character, the HBI offered by Lanxiang Building Group is the ideal metallic charge for steelmaking.

Physical and chemical specifications of our HBI make a superior product for the merchant HBI/DRI market, as a result of a low level of fines generated during transportation and handling, as well as less gangue, higher carbon, and higher metallization than that found in other HBI/DRI products.

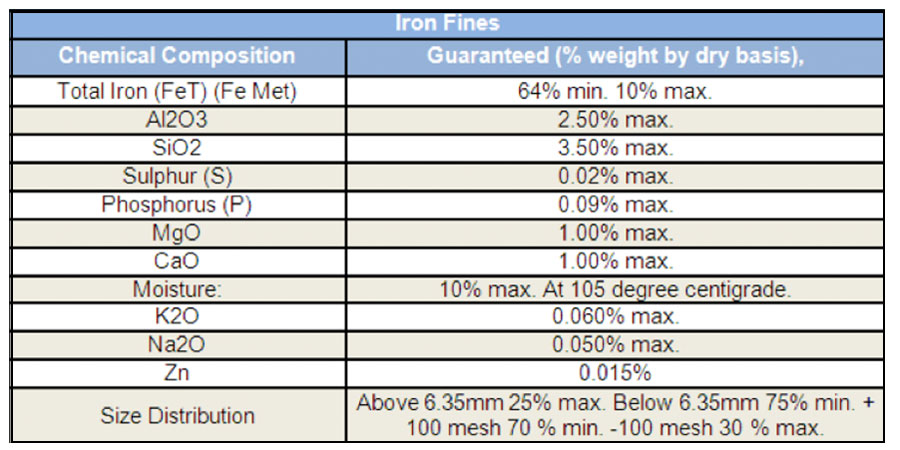

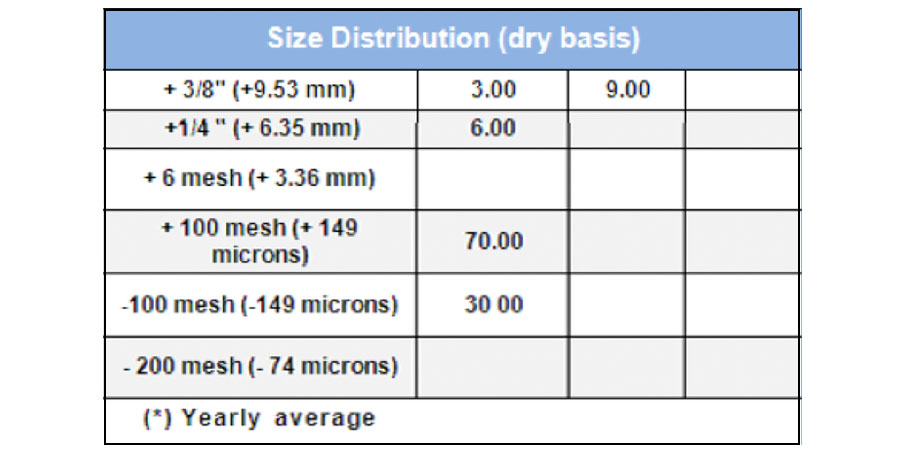

Iron Fines are a blend of byproducts that are generated in industrial processes such as pelletizing plants and/or direct reduced Iron Ore plants. The main difference between Iron Ore and Iron Fines is that Iron Ore comes directly from Iron Ore Natural Mines, and Iron fines are byproducts generated by a process. The Iron Fines offered by Globe Steel are a blend of byproducts from different DRI processes (Finmet, Midrex or HyL). The source of the material comes from the small particle matter picked up in the cooling system and collected in the sedimentation pond of such process.

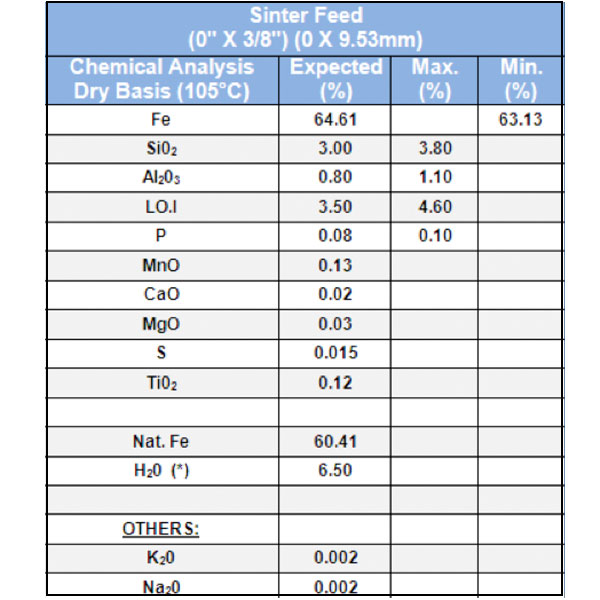

Coming from a DRI process, this unique material has a high Fe content material with around 8 % of metallic Fe content, and a very low Phosphorus, Sulfur, Alkalis and Zinc. It can be used as fresh sinter feed or as a pellet feed. Our Iron Fines present a 65 % of Fe content material, with 8 % Metallic Iron , and allows the blending pile to have enough room to blend the maximum reverted in-plant materials.

Depending on the sinter chemistry, more flue dust from blast furnaces than standard figures can be used. Process economy is then guaranteed. In the long run, the Iron Fines supplied by Globe Steel will help keep the sinter chemistry with low or very low Sulfur, Phosphorus, Alkalis and Zinc. It will prevent higher non-desired elements for blast furnace operation, or to increase sinter Fe content at a maximum depending on slag rate desired.

Parameter of Iron